General Description

Dried Glucose Syrup is a dehydrated form of glucose syrup, derived from starch hydrolysis. It is widely used in cosmetic and personal care formulations for its moisturizing, humectant, and emulsifying properties. This ingredient is available for bulk purchase, wholesale sales, and direct manufacture, making it a preferred choice for beauty brands and skincare companies.

Uses in the Cosmetics Industry

Dried Glucose Syrup is valued for its hydrating and texture-enhancing benefits, making it an essential ingredient in:

- Moisturizers and creams – Helps retain moisture and improves skin hydration.

- Hair care products – Conditions and enhances smoothness in shampoos and conditioners.

- Face masks and serums – Acts as a humectant, drawing moisture into the skin.

- Bath and body products – Enhances texture and stability in formulations.

Beauty brands and cosmetic manufacturers looking for wholesale Dried Glucose Syrup for sale prefer it for its natural humectant properties and compatibility with various formulations.

Side Effects & Hazards

Dried Glucose Syrup is generally safe for topical use, but some concerns include:

- Possible stickiness in high concentrations, which may affect product texture.

- May cause irritation in individuals with sensitive skin if used in excess.

- Moisture absorption may cause clumping during bulk storage or manufacturing if not stored properly.

To ensure quality, buy only cosmetic-grade Dried Glucose Syrup from reputable suppliers and follow proper storage guidelines.

Where to Buy Dried Glucose Syrup?

For businesses looking to buy Dried Glucose Syrup in bulk, many wholesale suppliers and manufacturers offer high-quality, cosmetic-grade Dried Glucose Syrup for sale. Whether for formulations, private labeling, or large-scale production, sourcing from trusted manufacturers ensures product purity and compliance with industry standards.

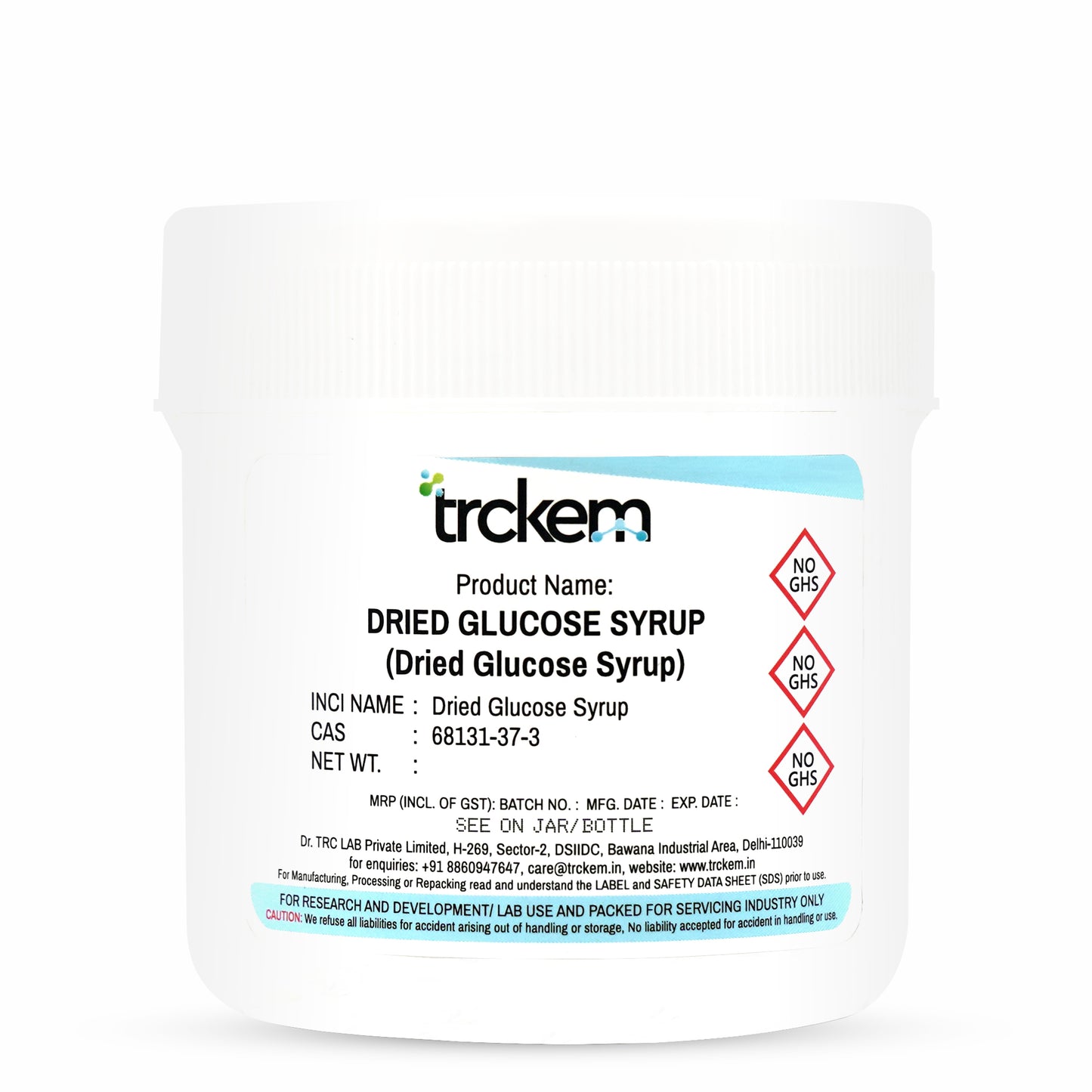

CAS Number: 50-99-7

INCI: Dried Glucose Syrup

Composition: Dried Glucose Syrup primarily consists of glucose, with small amounts of other carbohydrates and water. It is produced by the hydrolysis of corn starch, which breaks down the starch molecules into glucose molecules.

Purity Grade: No purity grade applicable

Appearance: Dried Glucose Syrup typically appears as a fine, white to off-white powder.

Solubility: Dried Glucose Syrup is highly soluble in water and forms clear solutions when dissolved.

Preservation: Dried Glucose Syrup itself does not require preservation as it is a dry, stable powder. However, it should be stored in a cool, dry place to prevent moisture absorption and caking.

Storage: Store in a closed container at a dry place at room temperature

Raw Material Source: Dried Glucose Syrup is derived from corn starch, which is obtained from corn kernels. Corn is a widely cultivated crop, and the raw material source may vary depending on factors such as geographical location and agricultural practices.

Manufacture: Dried Glucose Syrup is produced through a multi-step process. First, corn starch is obtained from corn kernels through wet milling. Then, the starch is hydrolyzed using enzymes or acids to break down the starch molecules into glucose. The resulting glucose syrup is then concentrated and dried to remove moisture, resulting in dried glucose syrup.

Animal Testing: Not animal tested

GMO: GMO-free (does not contain plant-derived components)

Vegan: Does not contain animal-derived components

Proposition: DRIED GLUCOSE SYRUP complies with relevant regulations and

guidelines.

Warning: Avoid contact with eyes and skin. Use appropriate protective equipment when handling.

THE STORY OF DRIED GLUCOSE SYRUP

Dried Glucose Syrup: The Natural Humectant & Binder for Smooth Cosmetic Textures

Dried Glucose Syrup is a spray-dried carbohydrate powder derived from starch hydrolysis. Used in both cosmetics and personal-care applications, it functions as a humectant, binder, and texture enhancer. It helps maintain product smoothness, improves moisture retention, and stabilizes powder and dry-blend formulations.

Starch-Derived Carbohydrates Processed for High Purity & Stability

Dried Glucose Syrup is produced by enzymatic or acid hydrolysis of starch from corn, wheat, or tapioca.

The resulting glucose-rich solution is spray-dried into a free-flowing, non-hygroscopic powder.

TRCkem provides cosmetic-grade Dried Glucose Syrup with:

• Controlled DE value (dextrose equivalent)

• Low moisture

• Excellent solubility

• High stability in dry and wet formulations

Bind. Hydrate. Smooth.

Key benefits in cosmetic and personal-care products:

✅ Acts as a humectant, helping retain moisture

✅ Functions as a binder in masks, powders & tablets

✅ Provides a smooth texture and dispersion in formulations

✅ Enhances skin-feel and softens product structure

✅ Stabilizes emulsions and dry blends

Used in: face masks, bath powders, cleansing powders, lotions, gels, scrubs, and some oral-care formulations.

Safe, Stable & Easy to Use in Dry or Aqueous Formulations

• Typical use level: 1–20% depending on function

• Easily soluble in hot or cold water

• Safe, non-irritating, and biodegradable

• Add directly to powder blends or dissolve into the water phase

• Store in airtight packaging to prevent moisture uptake

• Compatible with clays, starches, botanical extracts, surfactants & humectants

• Approved globally for cosmetic use (EU, US, India, ASEAN)

Formulator’s Queries, We Answered

1. What is Dried Glucoside Syrup?

Dried Glucoside Syrup is a plant-derived, mild surfactant and emulsifying agent commonly used in personal care formulations. It is produced through the reaction of glucose with natural fatty alcohols, creating a biodegradable, non-irritating ingredient ideal for gentle skincare and haircare products.

2. What is the CAS Number of Dried Glucoside Syrup?

The CAS Number of Dried Glucoside Syrup is (Insert CAS Number here – refer to supplier or regulatory database for accuracy).

3. What is the INCI Name of Dried Glucoside Syrup?

The INCI Name for Dried Glucoside Syrup is (Insert INCI Name here – confirm from the manufacturer or chemical database).

4. What are the applications of Dried Glucoside Syrup in the personal care industry?

Dried Glucoside Syrup is commonly used in:

Shampoos and hair cleansers for mild yet effective cleansing.

Facial cleansers and body washes for gentle foaming and hydration.

Baby care formulations due to its non-irritating nature.

Natural and organic cosmetics as a biodegradable surfactant.

5. What are the benefits of using Dried Glucoside Syrup in personal care products?

Mild Cleansing: Effectively removes dirt and oil without stripping moisture.

Biodegradable: Environmentally friendly and sustainable.

Non-Irritating: Gentle on the skin, making it ideal for sensitive skin formulations.

Good Foam Stability: Provides a smooth and rich lather.

6. Is Dried Glucoside Syrup safe for all skin types?

Yes, Dried Glucoside Syrup is considered safe for all skin types, including sensitive and baby skin, as it is derived from natural sources and has a low irritation potential. However, as with any ingredient, a patch test is recommended before use.

7. Is Dried Glucoside Syrup compatible with other cosmetic ingredients?

Yes, it is compatible with a wide range of surfactants, emulsifiers, and conditioning agents, making it a versatile ingredient in cosmetic formulations.

8. Does Dried Glucoside Syrup contain sulfates or parabens?

No, Dried Glucoside Syrup is sulfate-free and paraben-free, making it an excellent choice for clean beauty and natural formulations.

9. Is Dried Glucoside Syrup vegan and cruelty-free?

Yes, it is derived from plant-based sources and is typically vegan and cruelty-free. However, certification may depend on the supplier.

10. Where can I purchase Dried Glucoside Syrup?

Dried Glucoside Syrup can be sourced from cosmetic ingredient suppliers, specialty chemical distributors, and online marketplaces that cater to personal care and cosmetic formulation needs.