THE STORY OF MONOETHANOLAMINE

Monoethanolamine: The Essential pH Adjuster & Surfactant Builder for Cleansing Systems

Monoethanolamine (MEA) is a versatile organic compound widely used in cosmetic and home-care formulations as a pH adjuster, emulsifier, neutralizing agent, and surfactant builder.

Known for its strong alkalinity and reactivity, it helps optimize foaming, cleaning, and viscosity.

Commonly used in shampoos, detergents, creams, lotions, and industrial cleaners.

Produced by Reacting Ethylene Oxide with Ammonia for High-Purity MEA

MEA is synthesized through a controlled reaction between:

• Ethylene oxide

• Aqueous ammonia

followed by:

• Distillation

• Purification

• Safety-grade packaging

The result is a clear, hygroscopic, alkaline liquid used across cosmetics, pharmaceuticals, and industrial applications.

TRCkem supplies high-purity MEA (≥ 99%) suitable for cosmetic and detergent-grade formulations.

Neutralize. Stabilize. Boost Performance.

MEA adds multiple functional advantages:

✅ Neutralizes fatty acids to form soap and emulsifiers

✅ Adjusts pH in creams, lotions & shampoos

✅ Builds foam & cleaning strength in detergents

✅ Enhances viscosity & stability in surfactant systems

✓ Helps solubilize oils & active ingredients

Used in: shampoos, liquid detergents, household cleaners, shaving creams, metal-cleaning fluids & industrial formulations.

Powerful Alkaline Agent — Use with Precision & Controlled Handling

• Typical use level:

– 0.1–5% in cosmetics

– 2–15% in detergents & industrial cleaners

• Always add slowly to avoid overheating

• Strong base → handle with PPE (gloves, goggles)

• Avoid skin & eye contact; corrosive in concentrated form

• Store in tightly sealed containers away from heat & moisture

• Compatible with most surfactants, fatty acids & emulsifiers

• Not recommended for leave-on skincare

Formulator’s Queries, We Answered

1. What is Monoethanolamine (MEA)?

Monoethanolamine (MEA) is an organic compound that is commonly used as a pH adjuster, surfactant, and emulsifier in various personal care products. It is derived from ammonia and ethanol, and is used to modify the texture, stability, and consistency of formulations.

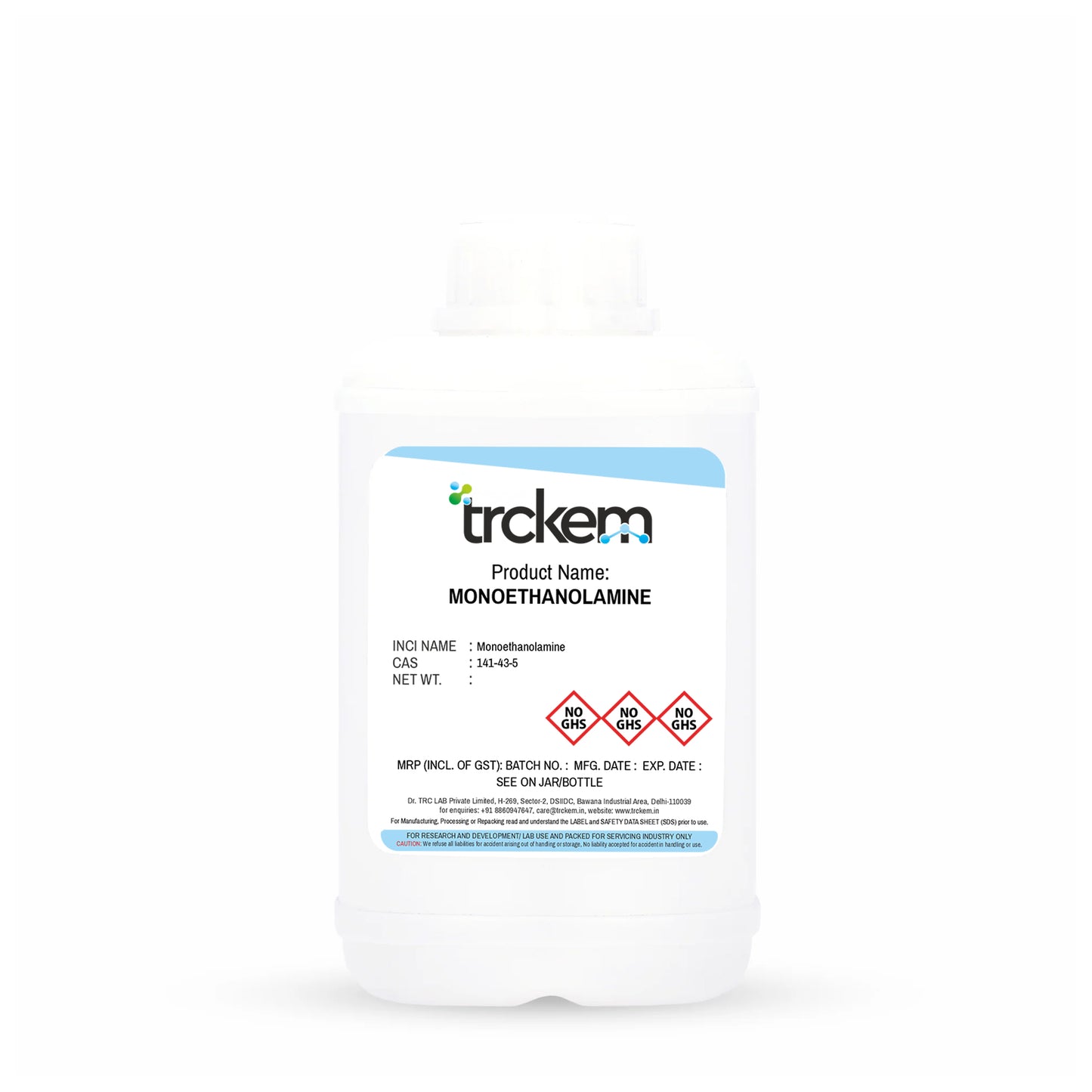

2. What is the INCI name and CAS number of Monoethanolamine?

CAS Number: 141-43-5

INCI Name: Monoethanolamine

3. What are the key benefits of Monoethanolamine in personal care formulations?

Acts as an alkaline pH adjuster to stabilize formulations

Functions as a surfactant and emulsifier in creams, lotions, and shampoos

Enhances the solubility and efficacy of active ingredients

Improves foaming properties in cleansing products

Helps to stabilize and thicken aqueous-based products

4. In what types of personal care products is Monoethanolamine commonly used?

Monoethanolamine is commonly found in:

Shampoos and hair conditioners

Facial cleansers and body washes

Creams, lotions, and moisturizers

Depilatory products (hair removal creams)

Acne treatment products

5. Is Monoethanolamine safe for use in cosmetics?

Monoethanolamine is generally considered safe for use in cosmetics when used within recommended concentrations. It helps to maintain the stability of products, but excessive use or prolonged exposure may cause skin irritation. It should be used with caution in leave-on products, particularly for individuals with sensitive skin.

6. Are there any safety concerns with Monoethanolamine in cosmetics?

While Monoethanolamine is commonly used in cosmetic formulations, it is important to avoid overexposure, as it can cause skin irritation in some individuals. Additionally, nitrosamine formation may occur in the presence of nitrates, so formulations should be carefully prepared to avoid this reaction.

7. Is Monoethanolamine derived from natural sources?

Monoethanolamine is synthetically produced through the reaction of ammonia and ethylene oxide. Although it can be derived from natural sources, the final product is considered synthetic.

8. What is the typical usage level of Monoethanolamine in formulations?

The typical concentration of Monoethanolamine in personal care products ranges from 0.1% to 2%, depending on its role as a surfactant or pH adjuster. Higher concentrations are generally used in formulations requiring more significant emulsifying or foaming effects